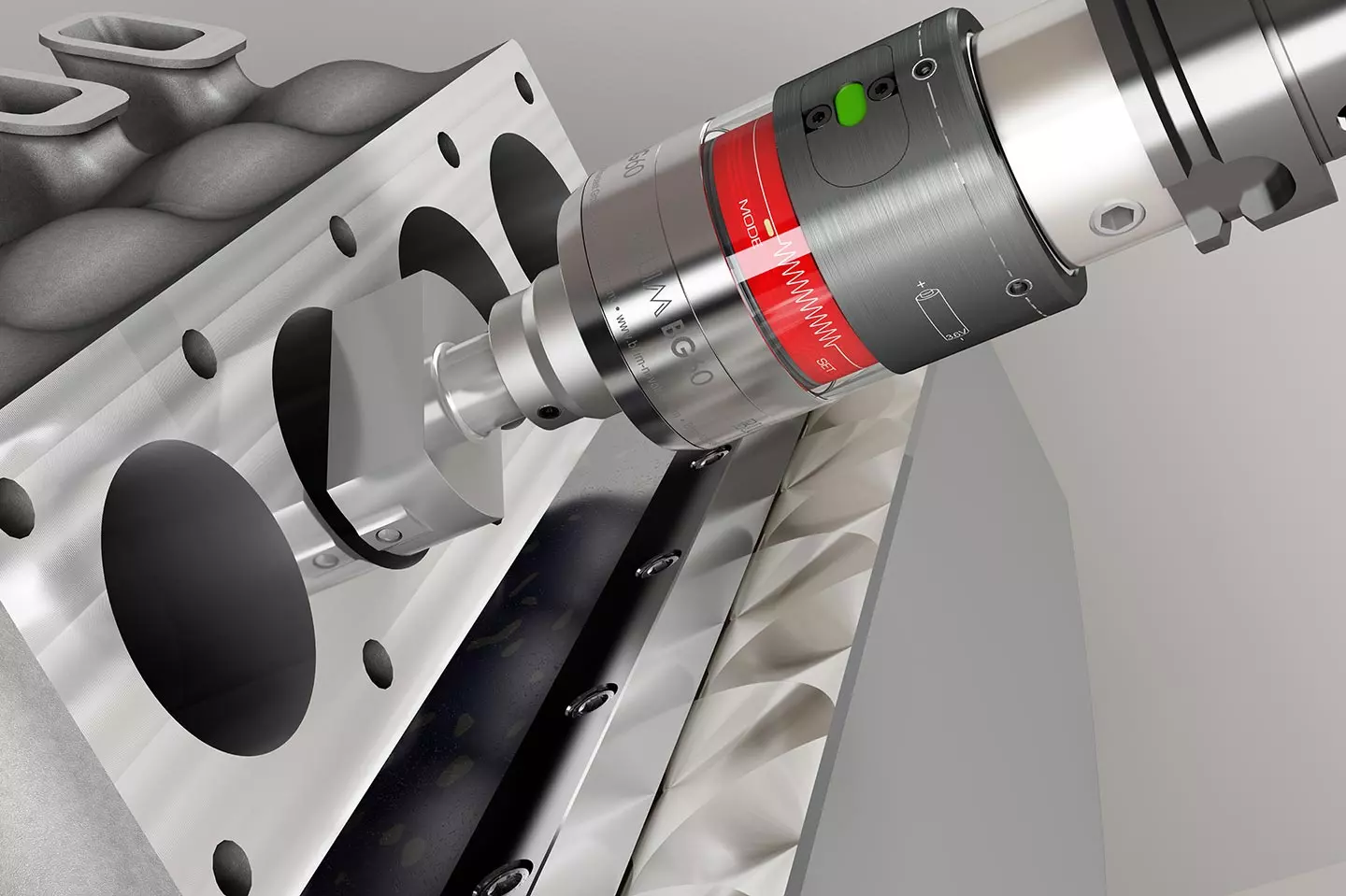

Boring is a common operation in machine shops, as well as in industries such as gun smithing and automotive. Performing boring operations requires a specific tool set, just as hole measurement demands precise measuring equipment.

Bore gauges are a set of measuring instruments for accurately measuring bores and holes, specifically the inside diameter of a hole or cylinder. Bore gauges come in a variety of forms and sizes and are used in many different applications, making them a vital tool for engineers and machinists. These gauging devices are made up of one anvil or two anvils. After they are inserted into a hole, the diameter can be measured after they are removed.

In addition to delivering very precise measurements, bore gauges have a wide range of accuracy, especially when compared to repeated measurements. In this post, we will take a look at the important basics you need to know when using a bore gauge.

Bore gauge types

There are several types of bore gauges available in the market for different purposes. These feature one to three anvils and are calibrated with gauge blocks or setting rings. Bore gauges can use a dial or digital readout to show the interior width of a hole, and some need a secondary device to read the measurement. Some of the commonly found bore gauges are dial bore gauge, telescopic bore gauge, small hole gauge, drill hole gauge, micrometre bore gauge, and cylinder bore gauge.

- Telescopic gauge comes with a telescopic rod which is retractable; this is used to measure deep holes. A cost-effective option, this tool needs a remote device like a multi metre to read the data.

- Dial bore gauge has a dial that shows the measurements. One can use the extendable holders to place inside holes with different diameters.

- Cylinder bore gauges can centralise the measuring head in a hole and can be used to measure bores up to 6 feet deep.

- Micrometre bore gauges have a variety of measuring heads that can be used to measure very small holes.

- As the name suggests, drill hole gauges are used to find the size of a drill bit.

- Small hole gauges are used to measure small bores and need secondary equipment like a micrometre or calliper to get the measurement.

Bore gauge sizes

Some bore gauges come with interchangeable extensions so that they can be used to measure different hole sizes. This means you can measure bores as small as 0.01 inches to holes as deep as 6 metres.

Zeroing a bore gauge

To zero a bore gauge, you first need to measure the gauge using a micrometre. This is to set it to the precise bore size. When the zero aligns with the needle, the bore gauge is ready to use. Not zeroing the gauge after usage could give you the wrong data.

Having calibrated gauges ensures that you have the data necessary to meet quality, safety, and compliance standards and regulations. Inaccuracies and errors can be costly.

Looking to buy a bore gauge? We offer numerous options to choose from if you are seeking a high-quality bore gauge at an affordable price.